SSDs have never been more affordable and here are the factors that have been helping drive prices down.

SSDS, HAVE NEVER BEEN MORE AFFORDABLE AND HERE ARE THE FACTORS THAT HAVE BEEN HELPING DRIVE PRICES DOWN.

As little as three years ago, a highend 256GB SSD can set you back as much as $500. Today, a typical high-end SSD of the same capacity costs less than half that amount. It’s amazing how much prices of SSDs have fallen. Of course, one of the reasons for that is because of volume production. Economies of scale mean that prices fall as production ramps up. But beyond this, there are also other factors at play including more efficient manufacturing processes and increased competition in form of third-party controllers.

When talking about more efficient manufacturing process, what we are really saying is that each wafer now gives us more NAND dies. This is achieved by shrinking the manufacturing process so that the NAND dies get smaller. At the present, we are looking at sub-20nm manufacturing processes. Toshiba’s latest MLC NAND is currently being produced using a 15nm manufacturing process, while Micron recently announced that it will begin production using a 16nm manufacturing process.

Unfortunately, we are fast approaching the limits of what can be achieved with shrinking manufacturing processes. To put it plainly, reducing the manufacturing process means squeezing more cells onto the die, which in turn means there is less space between each cell. And since each cell has to hold a charge, the interference from neighboring cells can sometimes disrupt or even inadvertently change the state of the cell that is next to it and cause the data to become corrupt. What this ultimately means is that there is a limit to how close cells can be put next to each other.

NAND manufacturers overcome this problem by increasing the amount of data that can be stored in a single cell. Imagine that you have 10 baskets and instead of holding a single ball each, they can now accommodate two balls each. You effectively double your storage. The idea applies to NAND memory too, though not quite so literally.

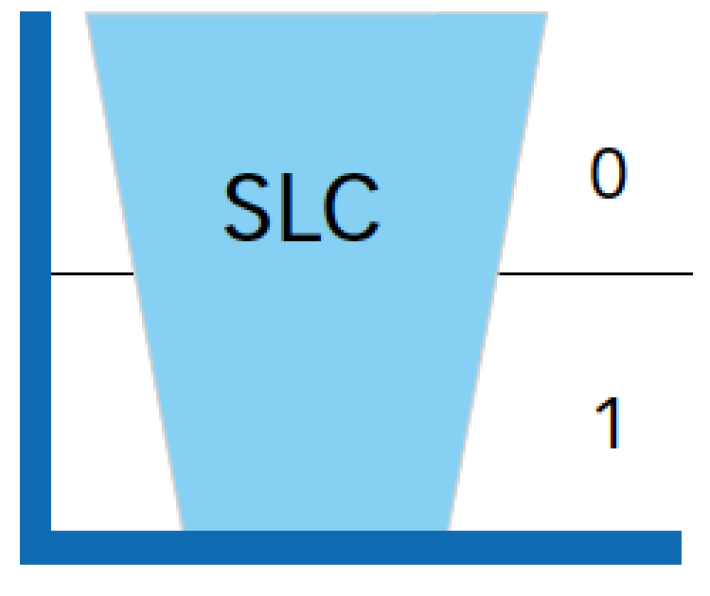

Early NAND flash was known as SLC NAND (single-level cell) as each cell held only a single bit of data. MLC NAND, which is the most commonly used type of NAND in consumer SSDs, typically refers to NAND chips with cells that hold two bits of data. Now, more SSD manufacturers are turning to TLC NAND (triple-Level cell), which stores up to three bits of data.

The next breakthrough in NAND technology is 3D Vertical NAND, but this technology is still very much in its infancy even though early products employing 3D Vertical NAND have been promising. As a result, TLC NAND will be, for the foreseeable future at least, the champion for driving prices of consumer SSDs down.

To be sure, TLC NAND is not a recent development. USB flash drives, as early as 2008, have employed the use of TLC NAND. However, endurance of these early NAND was poor and could not withstand the rigors of being used as a system drive. It is only recently in 2013 that Samsung put out the first consumer TLC NAND SSD - the SSD 840 Evo. And they were able to do so because of two things. The first is of course endurance of the dies itself are much better. Secondly, controller and firmware technology have both matured to the point where they could offer compelling enough performance and endurance.

In those early days, only Samsung had access to a controller capable of accommodating TLC NAND. One must realize that adding controller support for TLC NAND is much more complicated than just accommodating that extra bit of data per cell. The ECC engine (Error-correcting code) needs to be far more robust to deal with the more frequent and severe errors that TLC NAND drives would face. And Samsung was able to do so because it is one of the few SSD manufacturers that is manufactures its own NAND, develops its own controller and firmware.

Fortunately, the controller landscape has changed significantly. SanDisk and OCZ have both TLC NAND SSDs in the market. But more importantly, JMicron, Silicon Motion and Phison, have all announced new controllers in the past year that will offer support for TLC NAND and even 3D Vertical NAND. What this means is that smaller SSD manufacturers without the resources to develop their own controllers and firmware will now be able to source for controllers that can accommodate TLC NAND, allowing them to offer their own TLC NAND SSDs.

Obviously, such an arrangement does not promote much differentiation in terms of performance, but the increased competition is good for consumer as it can only drive prices down, especially in a market as price sensitive as SSDs. Without their own NAND production facilities, controller or firmware, these brands are really competing on price and whatever additional perks they can throw in, such as extended warranties or accessories. These will ultimately benefit consumers.

In summary, consumers can expect TLC NAND to be the driving force behind declining SSD prices. On top of that, the proliferation of TLC NAND SSDs will be aided by the greater availability of third-party controller offering support for such NAND memory. Here’s to more affordable SSDs!

For a very generic explanation - think of the different types of NAND as glasses of water. For SLC NAND, there are only two voltage states, so it’s easy to tell whether the level of water inside amounts to a “0” or “1”. TLC NAND has eight voltages stages, allowing it to pack more data in the same space. However, it gets hard to tell at a glance where the water level is up to, which is why the trade-off is poorer performance. With better measuring and control techniques, this is minimized.